A groundbreaking discovery has emerged from the Lawrence Berkeley National Laboratory, where researchers have unveiled an innovative, infinitely recyclable plastic that holds the potential to combat the escalating global pollution crisis.

By skillfully manipulating microbes, scientists have orchestrated the production of elements essential for a sustainable substitute to the 90% of plastics that currently remain non-recyclable. This breakthrough is particularly significant as numerous conventional plastics rely on limited and environmentally harmful petrochemicals as their fundamental constituents.

In a remarkable feat, the research team based in California has effectively reengineered microbes to synthesize biological alternatives to the initial components of a revolutionary recyclable plastic named poly(diketoenamine), or PDK for short.

“This is the first time that bioproducts have been integrated to make a PDK that is predominantly bio-based,” Dr. Brett Helms, the project leader, said.

“And it’s the first time that you see a bio-advantage over using petrochemicals, both with respect to the material’s properties and the cost of producing it at scale.”

He clarified that PDK, unlike conventional plastics, has the unique ability to be broken down into its original high-quality components and reshaped into novel products, all without any loss of quality.

In the beginning, PDKs utilized components sourced from petrochemicals; however, these constituents can be reengineered and synthesized using microorganisms.

After a persistent effort spanning four years, the scientists have successfully engineered E. coli to convert plant-derived sugars into key building blocks, specifically a molecule referred to as triacetic acid lactone (bioTAL). This achievement has led to the creation of a PDK variant with an impressive bio-content of approximately 80 percent.

“We’ve demonstrated that the pathway to 100 percent bio-content in recyclable plastics is feasible,” Jeremy Demarteau, a project scientist on the team, shared. “You’ll see that from us in the future.”

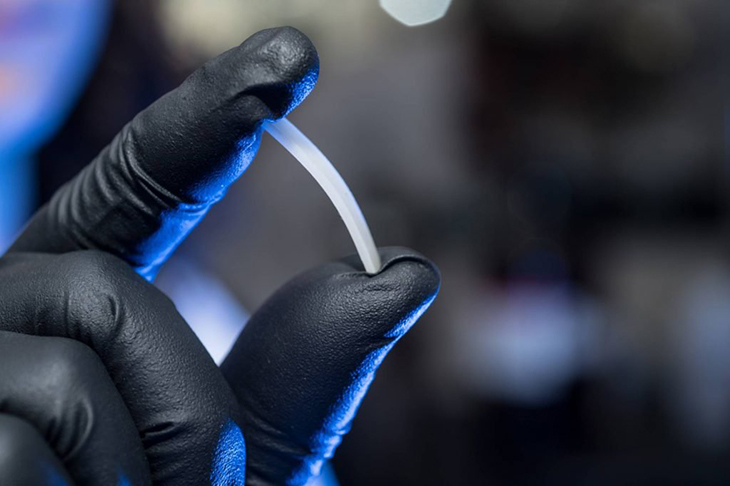

He mentioned that PDKs have versatile applications, spanning various products like adhesives, pliable items such as computer cables or watch bands, and even construction materials.

The integration of bioTAL into the material astonished researchers, as it broadened the operational temperature range by as much as 60 degrees Celsius when compared to the petrochemical variant.

This discovery, they believe, unveils the potential of employing PDKs in items necessitating precise working temperatures, such as sports equipment and automotive components like bumpers or dashboards.

“We can’t keep using our dwindling supply of fossil fuels,” said Professor Jay Keasling, senior faculty scientist in Berkeley Lab’s Biosciences Area. “We want to help solve the plastic waste problem by creating materials that are both biorenewable and circular – and providing an incentive for companies to use them.

“Then people could have the products they need for the time they need them, before those items are transformed into something new.”

The research, which has been published in the journal Nature Sustainability, further expands upon a previous environmental and technological study from 2021. This earlier analysis demonstrated that PDK plastic could achieve commercial competitiveness with traditional plastics when manufactured on a significant scale.

Corinne Scown, positioned as a staff scientist within Berkeley Lab’s Energy Technologies Area, remarked, how the outcomes of our recent findings are highly promising.

“We found that with even modest improvements to the production process, we could soon be making bio-based PDK plastics that are both cheaper and emit less CO2 than those made with fossil fuels.”

What are your thoughts? Please comment below and share this news!

True Activist / Report a typo